Instructions (click on an item)

Click a subject line in the index below to jump to that information:

Instructions, Questions & Help

Questions and Help (click on an item)

--Inkle/Belt Loom Warping Instructions (video)

--Assembly of a "Rigid" series loom (pdf file)

Opinions and Information about weaving on a jack loom: We have found that weavers develop a preference to certain types of looms. As with any other tool, you find one you are comfortable with and share this with other. Unfortunately some weavers feel their

preference should be shared by all other weavers and build a case to convince us that other looms need modifying or do not work well. One individual whose business happens to sell and support another type of loom even goes so far as to present a two page informational buyer’s guide explaining the problems with jack looms. As always keep an open mind as to the source and personal preferences of any information you get. As many current professional and novice weavers can attest, Jack looms weave all types of fabric easily and well, as they have been doing since Mr. Gilmore invented them in 1936.

preference should be shared by all other weavers and build a case to convince us that other looms need modifying or do not work well. One individual whose business happens to sell and support another type of loom even goes so far as to present a two page informational buyer’s guide explaining the problems with jack looms. As always keep an open mind as to the source and personal preferences of any information you get. As many current professional and novice weavers can attest, Jack looms weave all types of fabric easily and well, as they have been doing since Mr. Gilmore invented them in 1936.

Some Advise for Weaving with a Cloth/Warp Beam Inkle Loom

1. It is important to have your warp wrapped properly onto the Warping Beam. With Cloth/Warp Beam Inkle Looms you can make much longer warps than a "continuous warp" Inkle, and when weaving you will want your warp tight. As you wrap the warp on try to keep it flattened out and firmly wrapped. Use separators for the different layers. Short pieces of Venetian blinds are ideal, and wood "craft sticks" will also work (though thicker). The separators should extend past "limiters" (dowel pegs on the Inkle/Belt looms, Warping U Brackets on the Lap Loom, and adjustable steel pins on the Wave) so the warp threads will not spread out past and over the ends of the separators.

2. The warp fibers in Inkle weaving go through string or Texsolv heddles. This puts them very close together. With a tight warp and fibers against each other some fibers slide easily, but some are "sticky" and do not slide easily against each other when making your SHED. If they do resist you simply have to run your finger along the area the fibers are shifting through, loosening them up, as you switch layers for the shed. This works for any Inkle Loom using handmade string heddles (photo A), or the Wave loom or Texsolv Inkle Tower looms (photo B).

1. It is important to have your warp wrapped properly onto the Warping Beam. With Cloth/Warp Beam Inkle Looms you can make much longer warps than a "continuous warp" Inkle, and when weaving you will want your warp tight. As you wrap the warp on try to keep it flattened out and firmly wrapped. Use separators for the different layers. Short pieces of Venetian blinds are ideal, and wood "craft sticks" will also work (though thicker). The separators should extend past "limiters" (dowel pegs on the Inkle/Belt looms, Warping U Brackets on the Lap Loom, and adjustable steel pins on the Wave) so the warp threads will not spread out past and over the ends of the separators.

2. The warp fibers in Inkle weaving go through string or Texsolv heddles. This puts them very close together. With a tight warp and fibers against each other some fibers slide easily, but some are "sticky" and do not slide easily against each other when making your SHED. If they do resist you simply have to run your finger along the area the fibers are shifting through, loosening them up, as you switch layers for the shed. This works for any Inkle Loom using handmade string heddles (photo A), or the Wave loom or Texsolv Inkle Tower looms (photo B).

A

B

How long does it take to get a Gilmore Floor Loom after it is ordered?

The large Maple Floor Looms and the GEMII are made to order and their completion time varies as to how many parts have to be made, and existing orders. Once completed the freight shipping times can be several weeks.

The large Maple Floor Looms and the GEMII are made to order and their completion time varies as to how many parts have to be made, and existing orders. Once completed the freight shipping times can be several weeks.

Can I change my plain beam to a sectional beam? The early Compact series looms had an "open" type Warp Beam. The later floor models, and our current model, have the "closed" type Warp Beam of solid boards.

We stock sectional bars for the "closed" type warping beam. These are made with 3/8" maple dowels set on 2" centers. They attach right on top of the beam boards (see our "Floor Loom" page.)

Adding the sectional kit to a closed beam makes it about 3" taller. It is always good to check if there is clearance to the rest of the loom's structure as it turns around. beam.

We stock sectional bars for the "closed" type warping beam. These are made with 3/8" maple dowels set on 2" centers. They attach right on top of the beam boards (see our "Floor Loom" page.)

Adding the sectional kit to a closed beam makes it about 3" taller. It is always good to check if there is clearance to the rest of the loom's structure as it turns around. beam.

Open type Warp Beam

Closed type Warp Beam

Help! My warp beam spins when I release the brake. This can really be a problem for the warp, especially if you have sectional beams. It is always adviseable to release the pressure using the cloth beam system first before releasing the warp beam brake. Also, try taking some yarn or string and wrap it around the warp beam axle on the opposite end from the brake ratchet. This fills any space there might be to the slotted warp beam brackets. The resulting "drag" will keep the beam from spinning freely.

New looms have a block and spring system that prevents this spinning from happening. You can get the anti-spin system as a kit FOR THE COMPACT SERIES looms with WARP BEAM ARMS that are about 9 1/2" in overall length. It is not hard to install it yourself. Click here for the Anti-Spin kit installation instructions. Click for Anti-Spin pricing.

Can I change my 4 shaft Gilmore Loom to an 8 shaft? There are no kits available to change a Gilmore from 4 to 8 harness. Structurally there would be so much to replace you would probably be better off getting another loom.

How much is a used Gilmore Loom worth? This question we are frequently asked. It is impossible for us to determine the value of a loom without seeing it. There does not seem to be an increase in value for a real old "antique" Gilmore unless it is in perfect condition. There are certain things to look at when placing a value on an old loom. Here are some checks: 1) Are there water stains? Is the finish gone and the wood has a dried out feel? Has the loom seen lots of sunlight showing a dark patina in some areas and lighter bands where something covered the wood? 2) Are there any cracks in the wood? Look at the top of the castle, at the ends of the shuttle race (where the reed slot meets the beater leg). Are the lams or the harnesses warped (some warping will not affect the operation of the loom at all)? 3) Are the rubber cushions ( 2 under the jacks, and 2 at the underside of the lam guide tops) flattened or turned to goo? 4) Are the metal parts rusty? Check the spring steel heddle bars, the heddles, the lam chains, reed, etc. 5) Do both sides of the beater bar hit the castle at the same time? Do the beater bar legs have clearance as they move back and forth? 6) Are the straps on the beams in good shape? 7) Does the crank handle turn the warping beam, or does it spin freely?

If you plan on buying a used loom try to see it first. Not everyone sees things from the same perspective.

Can I disassemble the loom? It is not recommended that you do so. When your loom was assembled some parts were drilled and assembled in place. If you disassemble the loom make sure to mark every part as to which side or which place it goes. Sandpaper shims are sometimes added on the beater assembly to align everything and these must be put back in the same place. Metal washers between the jacks vary in thickness and need to be put back in the correct order. On very old looms the screws can rust in their holes and will break off if turned out. Because of this, and more, you can see why we do not recommend disassembly.

What types of Gilmore looms have been made ? Many types of looms have been made by our company from a 144 inch - 2harness loom, to several 16 inch - 4 harness looms. Listed below are the main types:

New looms have a block and spring system that prevents this spinning from happening. You can get the anti-spin system as a kit FOR THE COMPACT SERIES looms with WARP BEAM ARMS that are about 9 1/2" in overall length. It is not hard to install it yourself. Click here for the Anti-Spin kit installation instructions. Click for Anti-Spin pricing.

Can I change my 4 shaft Gilmore Loom to an 8 shaft? There are no kits available to change a Gilmore from 4 to 8 harness. Structurally there would be so much to replace you would probably be better off getting another loom.

How much is a used Gilmore Loom worth? This question we are frequently asked. It is impossible for us to determine the value of a loom without seeing it. There does not seem to be an increase in value for a real old "antique" Gilmore unless it is in perfect condition. There are certain things to look at when placing a value on an old loom. Here are some checks: 1) Are there water stains? Is the finish gone and the wood has a dried out feel? Has the loom seen lots of sunlight showing a dark patina in some areas and lighter bands where something covered the wood? 2) Are there any cracks in the wood? Look at the top of the castle, at the ends of the shuttle race (where the reed slot meets the beater leg). Are the lams or the harnesses warped (some warping will not affect the operation of the loom at all)? 3) Are the rubber cushions ( 2 under the jacks, and 2 at the underside of the lam guide tops) flattened or turned to goo? 4) Are the metal parts rusty? Check the spring steel heddle bars, the heddles, the lam chains, reed, etc. 5) Do both sides of the beater bar hit the castle at the same time? Do the beater bar legs have clearance as they move back and forth? 6) Are the straps on the beams in good shape? 7) Does the crank handle turn the warping beam, or does it spin freely?

If you plan on buying a used loom try to see it first. Not everyone sees things from the same perspective.

Can I disassemble the loom? It is not recommended that you do so. When your loom was assembled some parts were drilled and assembled in place. If you disassemble the loom make sure to mark every part as to which side or which place it goes. Sandpaper shims are sometimes added on the beater assembly to align everything and these must be put back in the same place. Metal washers between the jacks vary in thickness and need to be put back in the correct order. On very old looms the screws can rust in their holes and will break off if turned out. Because of this, and more, you can see why we do not recommend disassembly.

What types of Gilmore looms have been made ? Many types of looms have been made by our company from a 144 inch - 2harness loom, to several 16 inch - 4 harness looms. Listed below are the main types:

Rigid :

This loom was similar but bigger than the "compact" we make today. If you needed to move it through a doorway you would need to take it apart in several sections. This was easily accomplished with only taking apart a few bolts. The warping beam axle slid into a grove on the leg rails. The breast beam and the back top beam lifted off and are on square tenon pegs. The beater bar assembly lifted up and out of the loom. Over 550 "rigid" looms were made from the mid 1930's until 1971 and they eventually evolved into the "compact" series by 1970. Read the TRIVIA section below to see how many were made.

This loom was similar but bigger than the "compact" we make today. If you needed to move it through a doorway you would need to take it apart in several sections. This was easily accomplished with only taking apart a few bolts. The warping beam axle slid into a grove on the leg rails. The breast beam and the back top beam lifted off and are on square tenon pegs. The beater bar assembly lifted up and out of the loom. Over 550 "rigid" looms were made from the mid 1930's until 1971 and they eventually evolved into the "compact" series by 1970. Read the TRIVIA section below to see how many were made.

Rigid series loom. Notice the "open" warping beam axles go through the leg system rail.

X frame:

This loom folded up vertically making a "X" shape of the legs. This made it much narrower for storage and moving. You must always watch the beater bar assembly in the folded position, as it can swing out and hit the floor. Many weavers love this type and travel with the narrower ones to classes. Over 1150 "X" series looms were made from the mid 1930's until 1963. Read the TRIVIA section below to see how many were made.

This loom folded up vertically making a "X" shape of the legs. This made it much narrower for storage and moving. You must always watch the beater bar assembly in the folded position, as it can swing out and hit the floor. Many weavers love this type and travel with the narrower ones to classes. Over 1150 "X" series looms were made from the mid 1930's until 1963. Read the TRIVIA section below to see how many were made.

X Frame series loom

Compact:

This successful design was made for over 30 years and is still the basic structure of today's Gilmore Maple Floor Loom. For weavers it is still the strong workhorse of hand weaving.

GEM:

The Gem series has been made in 18 inch and 22 inch. It is a lighter loom for easier traveling. Today the GEM II model made is made in an 8 harness the 22 inch

This successful design was made for over 30 years and is still the basic structure of today's Gilmore Maple Floor Loom. For weavers it is still the strong workhorse of hand weaving.

GEM:

The Gem series has been made in 18 inch and 22 inch. It is a lighter loom for easier traveling. Today the GEM II model made is made in an 8 harness the 22 inch

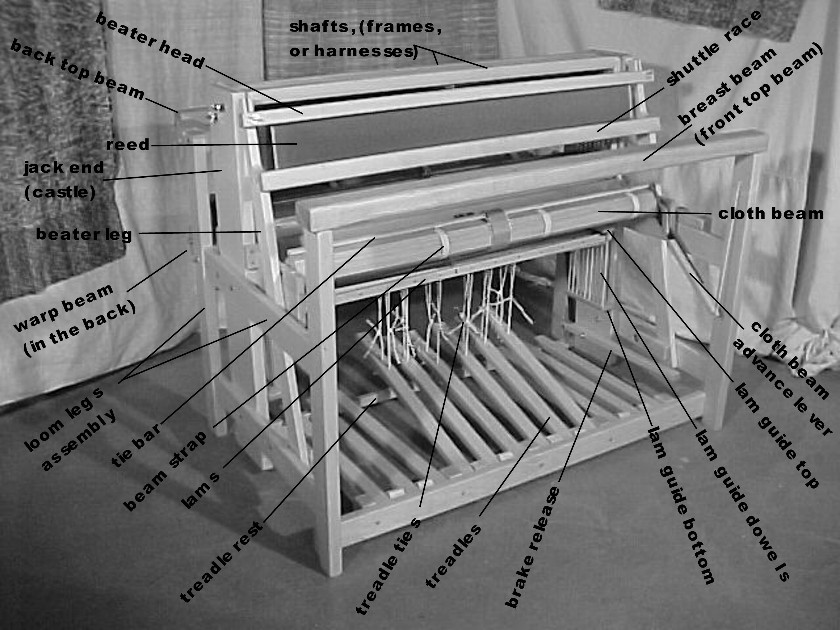

What are the names of the different parts of a jack loom ? Names can always help when asking about something on a loom. Even though there are different styles and series of looms most parts have standard names. However, some parts are known by several different names that are put in parenthesis.

Trivia

* Over 6,200 looms have been made by Gilmore Looms since the 1930's

* RIGID series looms:

Records for the Rigid series looms show the following sizes were made. Remember weaving width is not the overall loom

width. Code below is: weaving width (in inches) (then) harnesses (then) (number made).

So 22"-4h(40) would mean there were 40 twenty-two inch, 4 harness rigid looms made.

22"-4h(40), 22"-6h(1), 26"-4h(7), 26"-8h(5), 26"-9h(1), 32"-2h(2), 32"-4h(10), 32"-8h(4), 36"-4h(42), 36"-8h(15), 36"-10h(2), 40"-4h(38), 40"-8h(33), 40"-10h(2), 40"-12h(2), 44"-8h(1), 45"-4h(13), 45"-8h(19), 45"-12h(1), 46"-4h(50), 46"-6h(3), 46"-8h(130), 46"-10h(1), 46"-12h(5), 50"-4h(2), 50"-8h(1), 50"-12h(1), 52"-8h(1), 54"-4h(27), 54"-6h(4), 54"-8h(69), 54"-10h(2), 54"-12h(6), 60"-4h(7), 60"-8h(12), 60"-12h(1).

*X frame series looms:

Records for the "X" frame series looms show the following sizes were made. Remember weaving width is not the overall loom width. Code is: weaving width (in inches) (then) harnesses (then) (number made).

So 22"-4h(76) would mean there were 76 twenty-two inch, 4 harness "X" looms made.

22"-4h(76), 22"-6h(2), 22"-8h(1), 26"-4h(124), 26"-6h(2), 26"-8h(15), 32"-4h(52), 32"-6h(10), 32"-8h(24), 34"-4h(2), 36"-3h(1), 36"-4h(193), 36"-8h(22), 40"-4h(274), 40"-6h(11), 40"-8h(86), 40"-10h(1), 45"-4h(21), 45"-8h(13), 46"-4h(149), 46"-6h(15), 46"-8h(56), 50"-8h(1), 54"-4h(2), 60"-4h(1).

* Over 6,200 looms have been made by Gilmore Looms since the 1930's

* RIGID series looms:

Records for the Rigid series looms show the following sizes were made. Remember weaving width is not the overall loom

width. Code below is: weaving width (in inches) (then) harnesses (then) (number made).

So 22"-4h(40) would mean there were 40 twenty-two inch, 4 harness rigid looms made.

22"-4h(40), 22"-6h(1), 26"-4h(7), 26"-8h(5), 26"-9h(1), 32"-2h(2), 32"-4h(10), 32"-8h(4), 36"-4h(42), 36"-8h(15), 36"-10h(2), 40"-4h(38), 40"-8h(33), 40"-10h(2), 40"-12h(2), 44"-8h(1), 45"-4h(13), 45"-8h(19), 45"-12h(1), 46"-4h(50), 46"-6h(3), 46"-8h(130), 46"-10h(1), 46"-12h(5), 50"-4h(2), 50"-8h(1), 50"-12h(1), 52"-8h(1), 54"-4h(27), 54"-6h(4), 54"-8h(69), 54"-10h(2), 54"-12h(6), 60"-4h(7), 60"-8h(12), 60"-12h(1).

*X frame series looms:

Records for the "X" frame series looms show the following sizes were made. Remember weaving width is not the overall loom width. Code is: weaving width (in inches) (then) harnesses (then) (number made).

So 22"-4h(76) would mean there were 76 twenty-two inch, 4 harness "X" looms made.

22"-4h(76), 22"-6h(2), 22"-8h(1), 26"-4h(124), 26"-6h(2), 26"-8h(15), 32"-4h(52), 32"-6h(10), 32"-8h(24), 34"-4h(2), 36"-3h(1), 36"-4h(193), 36"-8h(22), 40"-4h(274), 40"-6h(11), 40"-8h(86), 40"-10h(1), 45"-4h(21), 45"-8h(13), 46"-4h(149), 46"-6h(15), 46"-8h(56), 50"-8h(1), 54"-4h(2), 60"-4h(1).

--Making a BEATER LOCK for your loom (pdf file)

Loosing your SHED with a tight warp on a Compact series loom. Jack looms are designed with a dip in the warp threads associated with the frames/shafts pulling it downward. If you are weaving with a tight warp (ie. for blankets, rugs, ..) and you lift some of the harnesses up you might find that the frames left down also become lifted with the tight warp and you loose some of your shed. An excellent way to solve this problem is by having the Back Top Beam 1 1/2" lower. It is suggested that only Gilmore Looms or an experienced wood worker attempt to do any cutting or drilling on your loom. However, there is a solution any one should be able to do by "flipping the Back Top Beam". A full set of instructions can be viewed by clicking on this link: "Flipping the Beam".

THE BLACK GOO, flat, or deteriorated cushion strips: After many years of storage, especially in hot conditions the 4 foam rubber cushion strips on a loom will go bad. Sometimes they flatten from the frames/shafts sitting on them, or worse they can turn into a black goo. This sticks to the frames and to the lamms and keep them from working properly. There are two sets of two on each side of the loom. On each side one "strip" will be under the Jacks ("jacks" act as scissors to lift the frames). The other strip will be above the end of the Lams on the Top Lam Guide.("lams" have holes and ties that go to the foot Treadles) . New adhesive backed rubber strips can be purchased from Gilmore Looms (See the page "Parts/Materials" on this website). The old ones will need to be scraped off then cleaned up with a non-oily solvent such as paint thinner. Do not use something that will make the cleaned surface unable to hold the adhesive on the back of the new cushions. The ones on the Top Lam Guides also have tacks holding them from peeling off. (A direction sheet and new tacks come with orders of replacement cushion strips.)

It is easiest to get under the loom or lean the loom over to get the cushions and tacks on the Top Lamm Guide off. You can also remove the Top Lam Guide (one screw) carefully and pull it outward then remove it from the dowels. On old looms or ones that got damp the Lam Guide screws can be stuck tight and could break when trying to get them out. If you remove them make sure to put the left and right Top Lam Guides back to the side they came from.

It is easiest to get under the loom or lean the loom over to get the cushions and tacks on the Top Lamm Guide off. You can also remove the Top Lam Guide (one screw) carefully and pull it outward then remove it from the dowels. On old looms or ones that got damp the Lam Guide screws can be stuck tight and could break when trying to get them out. If you remove them make sure to put the left and right Top Lam Guides back to the side they came from.

What is the best wax to put on the finish of my loom? We have found that many furniture polishes, especially liquid ones, can sink into the wood if it is dry. This makes it difficult to later re-coat with lacquer or other sealing finishes. If your loom still has its finish on it we recommend using a clear paste wax that has carnauba wax in it.

My loom is very dry and the finish is gone. What can I put on it? The loom originally had a clear lacquer finish. If there are stains they will be difficult to get out without loosing the patina of the loom's wood. You can lightly sand the surface smooth with 220 grit sandpaper, being careful not to sand too much on edges and corners as these will become lighter looking than the aged wood of an old loom. Then apply a lacquer type finish, we find great success with semi-gloss DEFT finish. Sand again lightly with the 220 grit sandpaper. Dust off. Apply a paste wax (see next question). Do NOT use water based cleaners on wood with a poor finish. It will raise the wood grain.

Can I oil squeeks or sticky parts? Using WD-40 or petroleum based oil products are NOT a good idea on wood. The wood acts like a sponge. The best thing to do is clean the problem parts, but it is tricky taking some things apart. Most all of the moving parts on a Gilmore loom should be loose enough so they do not need lubrication. There might be another problem. A small amount of dry bar soap that has glycerin in it can be used if needed.

Is there any way to clean the rust off the non-stainless spring steel heddle bars? There are probably many ways. One way that we have found successful follows: 1) Using the Orange Hand Cleaner with pumice or rust remover chemicals scrub off the rust. 2) Rinse with water and dry 3) Use cold bluing (example: Birchwood Casey Perma Blue) to seal and darken the metal. 4) Wipe a very small amount of light machine oil (as used on sewing machines, or "3-In-One" type) over the bars. Then wipe off any excess.

Can I get parts for my older Gilmore Loom? Our company still stands behind all of our looms. You may order replacement parts for your Gilmore. If it is a "compact" loom we usually have the parts in stock. If it is a model not currently being made we will be glad to make parts. Some parts are common to all Gilmore's, such as the metal ratchets and dogs, rubber cushions, straps, heddles, etc.

How can I tell if a loom is an authentic Gilmore Loom? Except for a very few looms, prior to 1940, all Gilmore's have the company name and address burned into the front and back jack bars. There are other indicators, such as tool marks and assembly, that help determine if it is authentic. (click here for help identifying a Gilmore model)

Is there anyway to tell the age of a Gilmore Loom? Early Gilmore's do not have dates on them. From the 60's and 70's onward

many were dated with small stamped numbers on the wooden handle of the cloth beam advance lever. After 1999 looms carry a serial number on the front jack bar. (click here for more information about finding the numbers)

If the address of our company (burned on the front and back jack bars) is 1032 Broadway Avenue then the loom was made after October 1957, before that looms would show the address as Commerce Street. However, if you know some of the following items we might be able to look the loom up in our database, which covers from 1937 to the present. (Original customer's last name, loom size and number of harnesses, city and state loom originally went to.)

many were dated with small stamped numbers on the wooden handle of the cloth beam advance lever. After 1999 looms carry a serial number on the front jack bar. (click here for more information about finding the numbers)

If the address of our company (burned on the front and back jack bars) is 1032 Broadway Avenue then the loom was made after October 1957, before that looms would show the address as Commerce Street. However, if you know some of the following items we might be able to look the loom up in our database, which covers from 1937 to the present. (Original customer's last name, loom size and number of harnesses, city and state loom originally went to.)

Gilmore Looms

1032 N. Broadway Ave.

Stockton, CA 95205-3928

Phone: (209) 463-1545

weavinginfo@gilmorelooms.com

1032 N. Broadway Ave.

Stockton, CA 95205-3928

Phone: (209) 463-1545

weavinginfo@gilmorelooms.com