Weaving Equipment

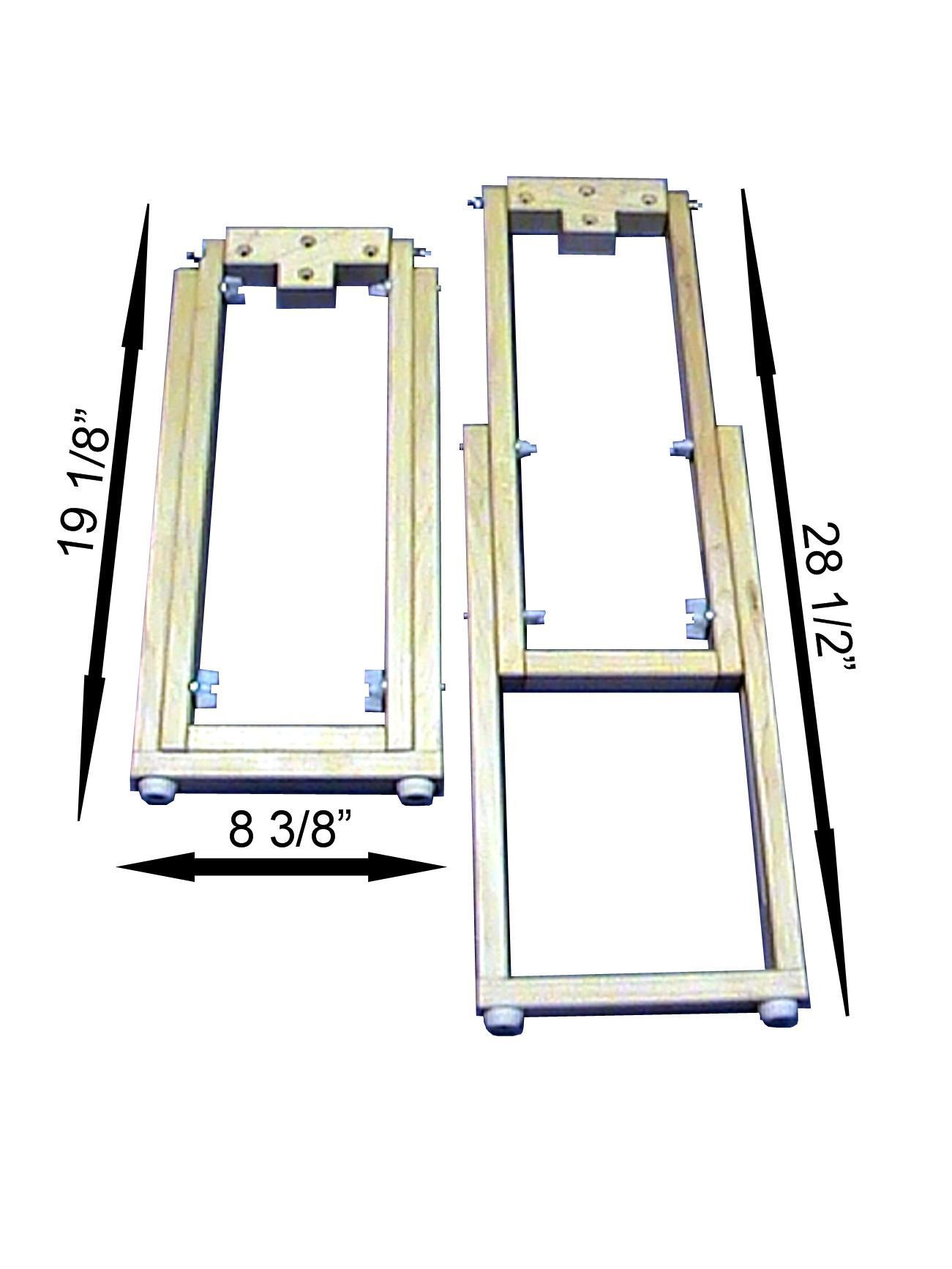

Gilmore Portable Loom Stand

This stand is made of hard maple and mounts to the bottom of the Gilmore Inkle Loom, the Gilmore Wave, and will fit other table looms. It is easy to mount with 4 screws to the bottom of any table or portable loom with a solid bottom of at least 3/4 inch thick. The length is adjustable so you can use your loom while sitting in a chair, or couch. It can also be used to weave vertically on a table. The pivot axles can be adjusted so they swing tightly or loosely. This makes it easy to work from a sitting position and allows you to rock back and forth with your weaving movements. When not in use the whole assembly folds up under the loom and only adds about 1 inch under the loom.

.Price Information

.Price Information

Gilmore Bench

The Gilmore Bench is made of solid hardwood maple. The top is 13 1/2 in. x 30 in.. The bench is tilted to the front making it easier on your back and to allow more comfortable treadle contact. Bench height is 22 1/2" in the front and 23" in the back. The drawer has maple ends and poplar sides and It slides through both ends for easier access. Price Information

The Gilmore Bench is made of solid hardwood maple. The top is 13 1/2 in. x 30 in.. The bench is tilted to the front making it easier on your back and to allow more comfortable treadle contact. Bench height is 22 1/2" in the front and 23" in the back. The drawer has maple ends and poplar sides and It slides through both ends for easier access. Price Information

For quick item location - Click on aTitle below

Shuttles

Rug and Stick Shuttles

Rug Shuttles are handmade from hardwood maple

and maple dowels.

Stick shuttles are handmade from poplar.

Price Information

and maple dowels.

Stick shuttles are handmade from poplar.

Price Information

A. (right) The Large Rug Shuttle is 1 3/4" wide x 2 5/8" high x 20" long.

B. (right) The Small Rug Shuttle is 1 3/4" x 2 5/8" x 10" long.

C. (right) The Stick Shuttle is 1/4" thick x 1 1/4" wide x 13" long. (unfinished)

B. (right) The Small Rug Shuttle is 1 3/4" x 2 5/8" x 10" long.

C. (right) The Stick Shuttle is 1/4" thick x 1 1/4" wide x 13" long. (unfinished)

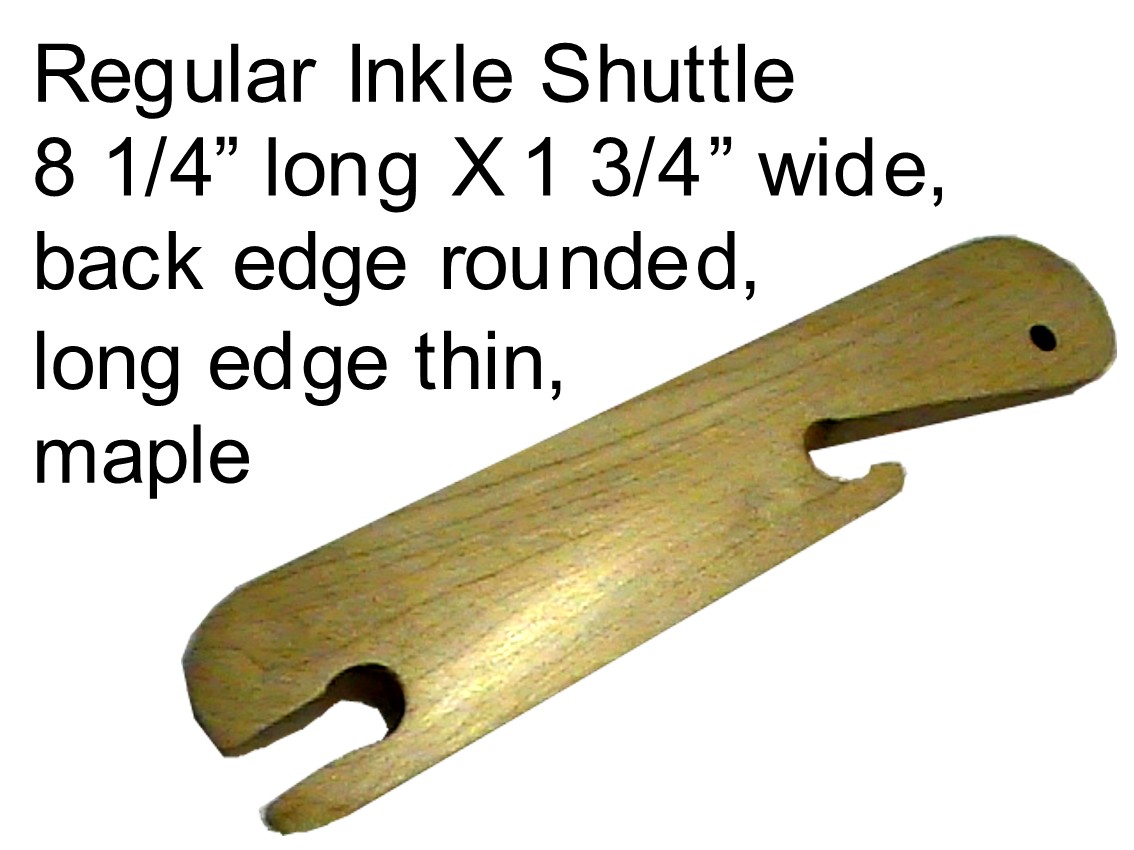

Inkle Type Shuttles These shuttles are made from maple, hickory and other beautiful hardwoods. Price Information

Wave Loom Shuttles are made with a flat edge to turn up and hold the shed, and a tapered edge to pack the weavings.

The Warping Wedge is another need-to-have tool for warping. A Warping Wedge placed under the frames or shafts will lift them in a stairstep pattern. In this position it is easy to see which frame's heddles you are working on.

A Warping Wedge can be placed to lift front to back or back to front. It will work on all Gilmore looms. Price Information

A Warping Wedge can be placed to lift front to back or back to front. It will work on all Gilmore looms. Price Information

Warping Wedge

Gilmore Raddles

Regular Reed Slot Raddle: These raddles are made to replace the reed in the reed slot on the Beater Bar. They are made of maple and the dowels are spaced on 1" centers..There lengths vary for the different loom weaving widths.

Price Information

Price Information

Front/Back Raddle: The Front/Back Raddle is a raddle that can be mounted on either the front (breast) beam or the back top beam. It will fit all "Gilmore" and "Compact" series looms. When mounted on the beams it can be set to be an open raddle or a closed raddle. It comes with a set of special clamps that will not hurt the beams. It can also take the place of the reed in the shuttle race reed slot.Price Information

Open Raddle

Closed Raddle

Some Advice for Weaving with an Inkle Loom

1. It is important to have your warp wrapped properly onto the Warping Beam. With Cloth/Warp Beam Inkle Looms you can make much longer warps than a "continuous warp" Inkle, and when weaving you will want your warp tight. As you wrap the warp on try to keep it flattened out and firmly wrapped. Use separators for the different layers. Short pieces of Venetian blinds are ideal, and wood "craft sticks" will also work (though thicker). The separators should extend past "limiters" (dowel pegs on the Inkle/Belt looms, Warping U Brackets on the Lap Loom, and adjustable steel pins on the Wave) so the warp threads will not spread out past and over the ends of the separators.

2. The warp fibers in Inkle weaving go through string or Texsolv heddles. This puts them very close together. With a tight warp and fibers against each other some fibers slide easily, but some are "sticky" and do not slide easily against each other when making your SHED. If they do resist you simply have to run your finger along the area the fibers are shifting through, loosening them up, as you switch layers for the shed. This works for any Inkle Loom using handmade string heddles (photo A), or the Wave loom or Texsolv Inkle Tower looms (photo B).

1. It is important to have your warp wrapped properly onto the Warping Beam. With Cloth/Warp Beam Inkle Looms you can make much longer warps than a "continuous warp" Inkle, and when weaving you will want your warp tight. As you wrap the warp on try to keep it flattened out and firmly wrapped. Use separators for the different layers. Short pieces of Venetian blinds are ideal, and wood "craft sticks" will also work (though thicker). The separators should extend past "limiters" (dowel pegs on the Inkle/Belt looms, Warping U Brackets on the Lap Loom, and adjustable steel pins on the Wave) so the warp threads will not spread out past and over the ends of the separators.

2. The warp fibers in Inkle weaving go through string or Texsolv heddles. This puts them very close together. With a tight warp and fibers against each other some fibers slide easily, but some are "sticky" and do not slide easily against each other when making your SHED. If they do resist you simply have to run your finger along the area the fibers are shifting through, loosening them up, as you switch layers for the shed. This works for any Inkle Loom using handmade string heddles (photo A), or the Wave loom or Texsolv Inkle Tower looms (photo B).

A

B

Front Beam Cloth Pocket

This pocket is made to fit a "Gilmore Maple" or "Compact" series loom, and the GEM looms. A sturdy canvass is supported by steel bars and hardwood maple ends. This allows you to have all your shuttles and accessories within easy reach. It is easily removed as needed. The mounting brackets are cushioned metal and a Velcro system.

Click Here for pricing information)

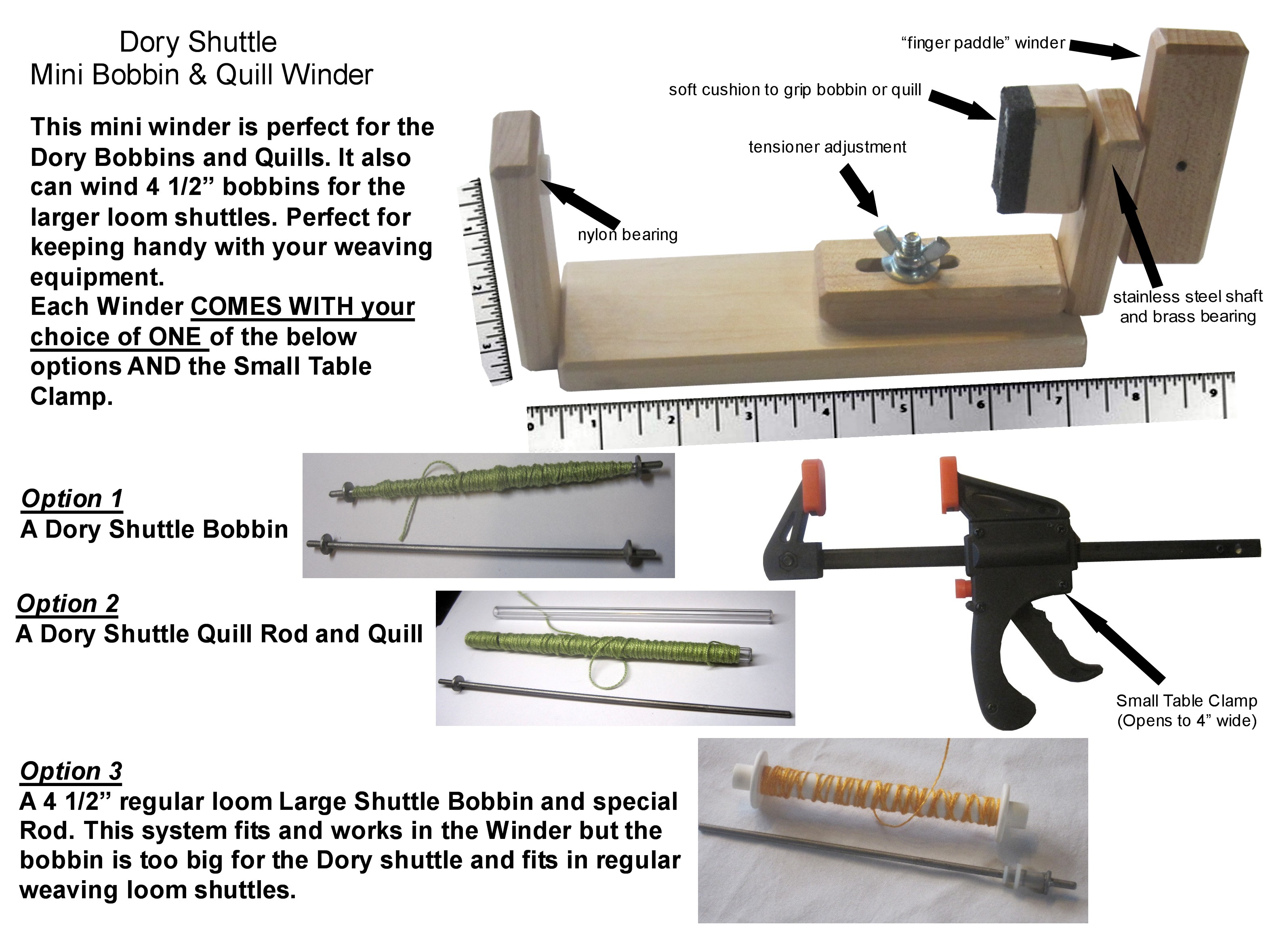

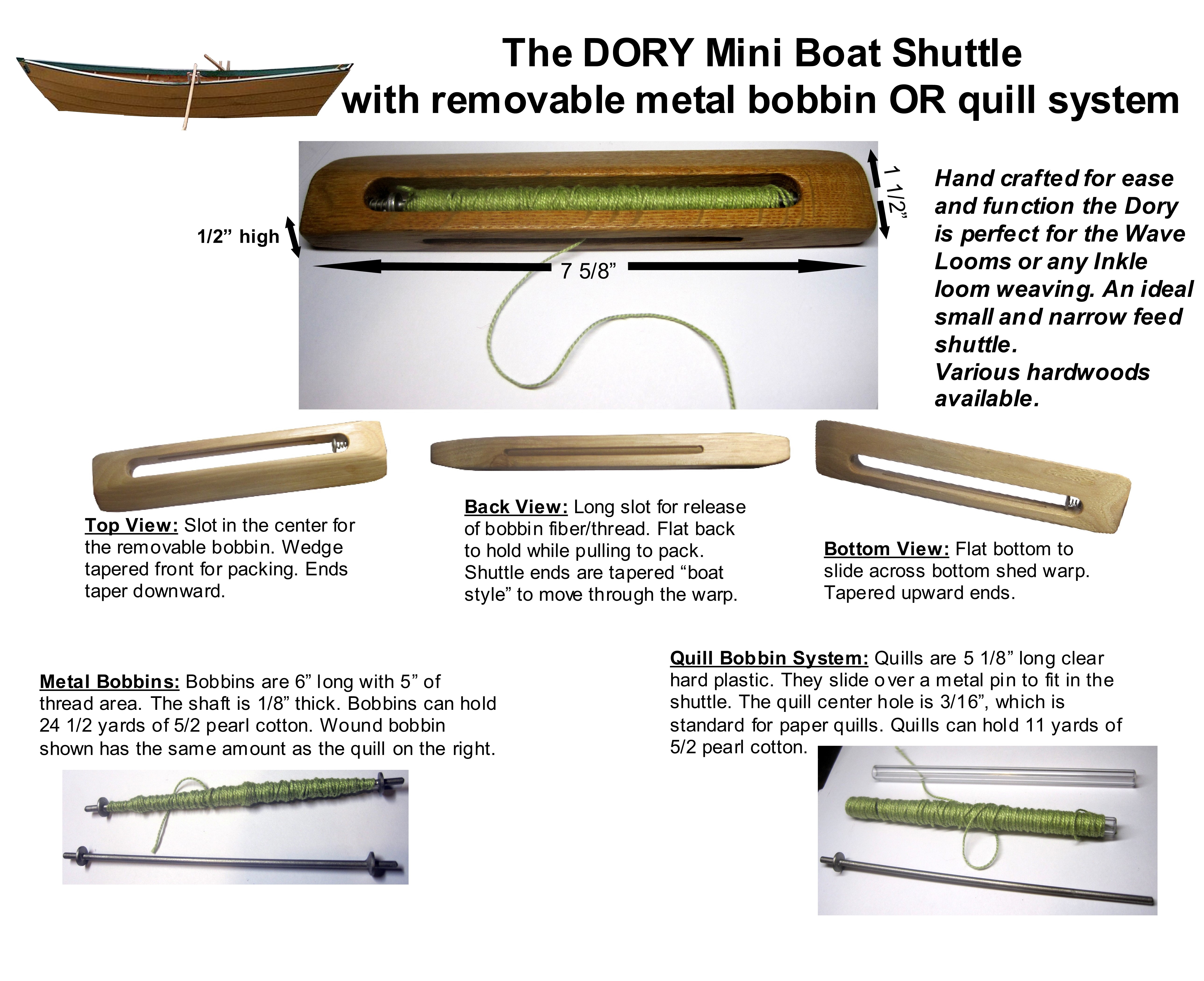

TAKE A DORY OUT FOR A RIDE ON THE WAVES Price Information

Watch video Below to learn

more about the DORY Shuttle

more about the DORY Shuttle

Watch video Below to learn

more about the DORY Bobbin

and Quill Winder

more about the DORY Bobbin

and Quill Winder

**The DORY Shuttle comes with 1 Bobbin or Quill System**

**Both the Bobbin and the Quill System are interchangeable within the * *SAME Shuttle, so you only need one shuttle to use either or both. **

Gilmore Compact & Maple Loom

GEM II Loom

Outside view of end brackets.

Cloth Pocket for X Frame series Gilmore Loom

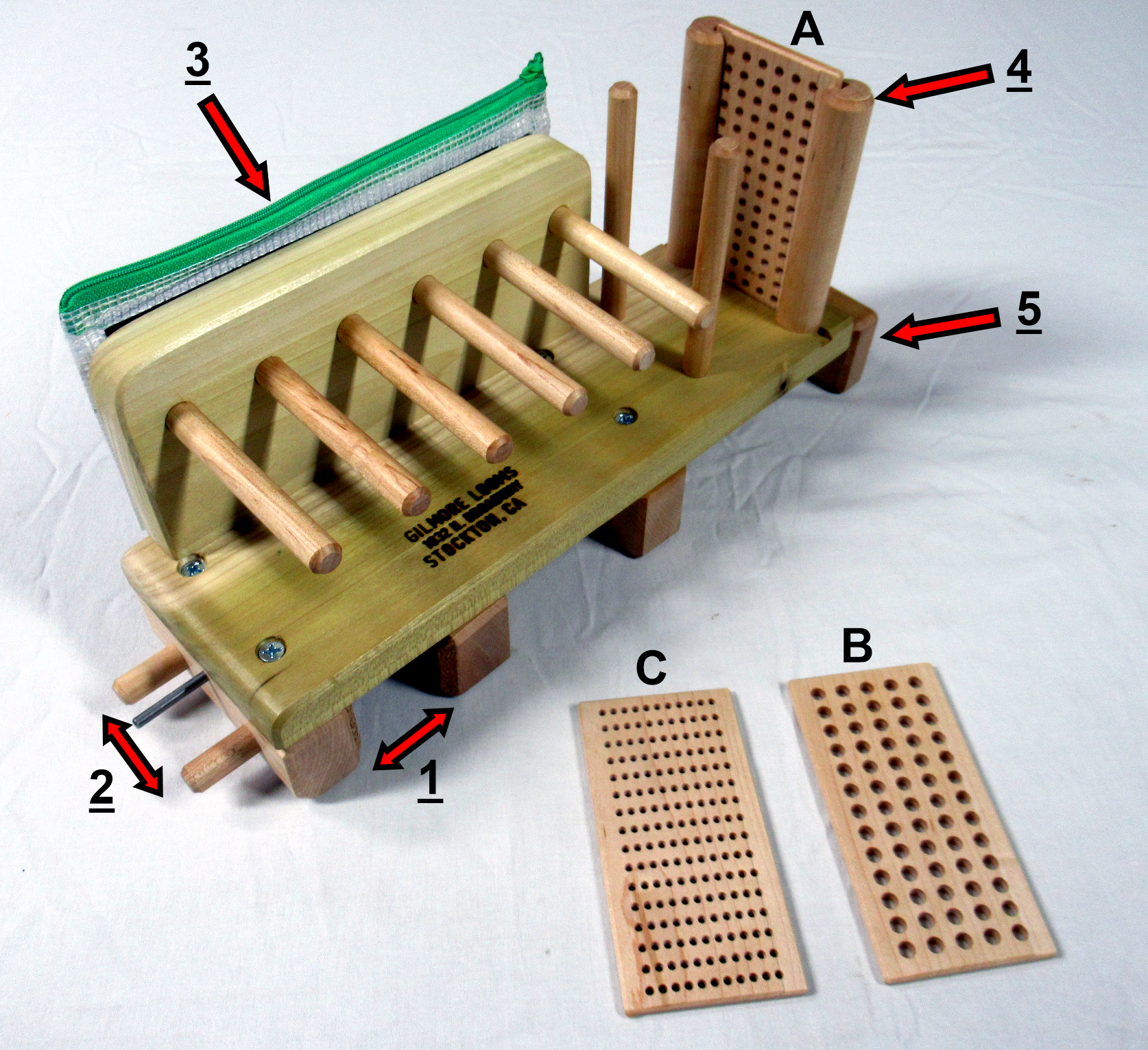

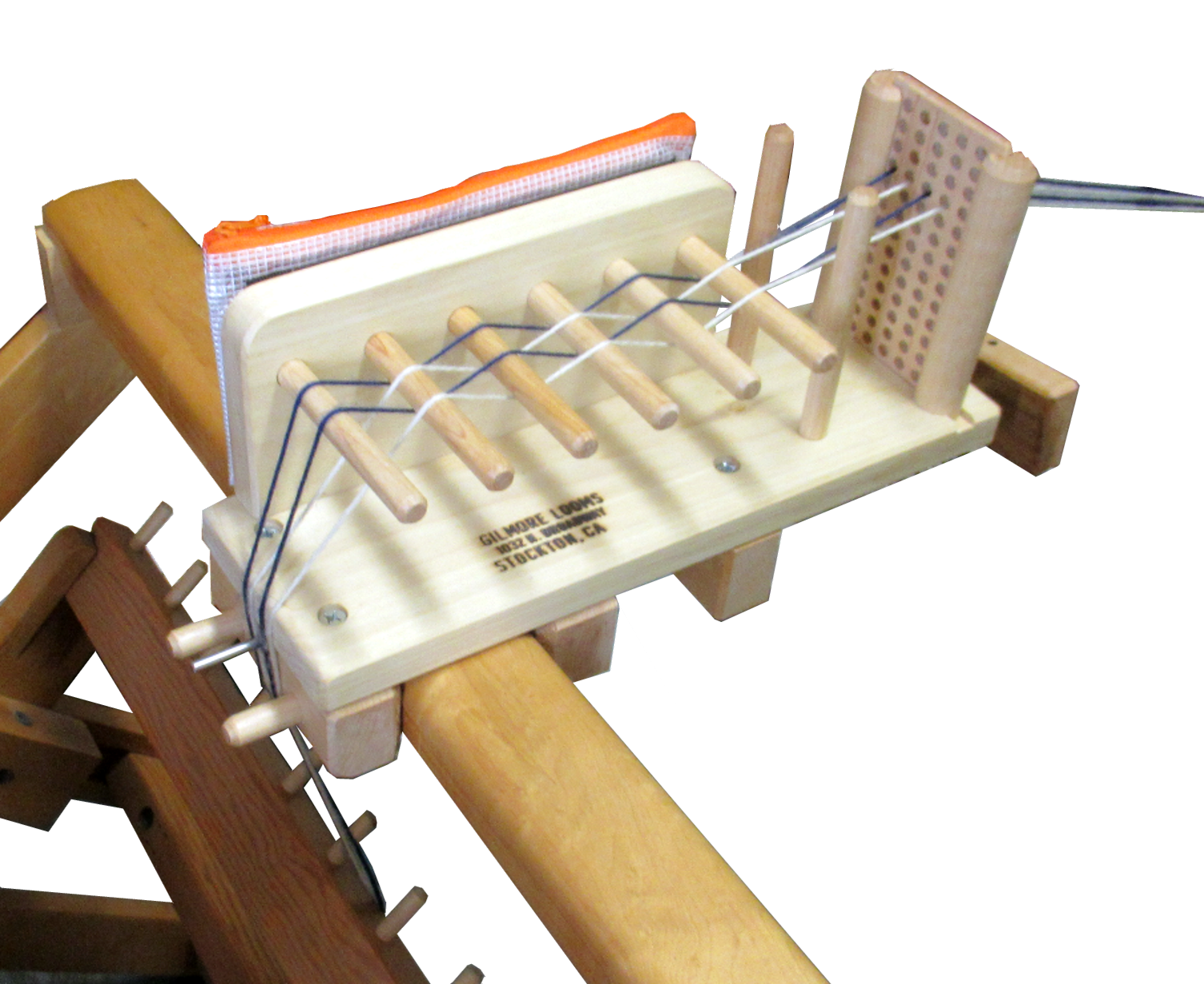

Universal Sectional Beam Tensioner

Approximately 18" x 5" x 8" high

* An adjustable Tensioner that can fit most all loom beams with the ability to warp large numbers of different sized threads. Run the warp threads through the cards then alternate over under the Tension Pegs to keep your "cross". Then down either as a 2" or 1" spread to the Sectional Beam.

Click Here for pricing information

* An adjustable Tensioner that can fit most all loom beams with the ability to warp large numbers of different sized threads. Run the warp threads through the cards then alternate over under the Tension Pegs to keep your "cross". Then down either as a 2" or 1" spread to the Sectional Beam.

Click Here for pricing information

#1. The Clamp is soft cork covered and can be adjustable to beams from 1 inch to 5 inches.

#2. The Feed Guides can be used for 2" sectional pin spacing or guide for 1 inch sectional spacing.

#3. A zippered storage bag is mounted on the back to hold the Tread Feed Cards.

#4. Two maple guide posts hold the Thread Feed Card being used.

#5. A large maple handle and steel rod lock the Clamp (marked #1)

#6. Three 5 1/4" x 2 3/4" wood cards come with each Tensioner providing many possible warp threads and thread sizes.

Card A.. with 84 holes, each 3/8" diameter

Card B.. with 65 holes, each 1/4" diameter

Card C.. with 176 holes, each 3/6" diameter

#2. The Feed Guides can be used for 2" sectional pin spacing or guide for 1 inch sectional spacing.

#3. A zippered storage bag is mounted on the back to hold the Tread Feed Cards.

#4. Two maple guide posts hold the Thread Feed Card being used.

#5. A large maple handle and steel rod lock the Clamp (marked #1)

#6. Three 5 1/4" x 2 3/4" wood cards come with each Tensioner providing many possible warp threads and thread sizes.

Card A.. with 84 holes, each 3/8" diameter

Card B.. with 65 holes, each 1/4" diameter

Card C.. with 176 holes, each 3/6" diameter

Gilmore Looms

1032 N. Broadway Ave.

Stockton, CA 95205-3928

Phone: (209) 463-1545

weavinginfo@gilmorelooms.com

1032 N. Broadway Ave.

Stockton, CA 95205-3928

Phone: (209) 463-1545

weavinginfo@gilmorelooms.com